I've been doing some more experimentation. Along with the new hotend and fan for my 3D printer, I also ordered a can of spray putty - I've been told that it is better than filler primer and wanted to try it for myself. I used it on another scrap piece from my Type S. I applied one coat all over, then sanded it down. I was simultaneously testing the cheaper own-brand sanding pads from Wilko. For the first pass I used the coarse/medium pad. With that done, I applied another coat of spray putty to half of each face, then sanded it down with the medium/fine pad.

As with the filler primer, the main problem is that it does fill in the panel lines - I need to get better at cleaning those back out. It's particularly difficult with some of the less recessed details. It also has to be done after sanding as you can't see them clearly until then.

I will say this much - it does do a better job of filling in the layer lines than filler primer; each coat was about the equivalent of two coats of filler primer. It's also cheaper - I'll definitely be using it when I prep my Type S.

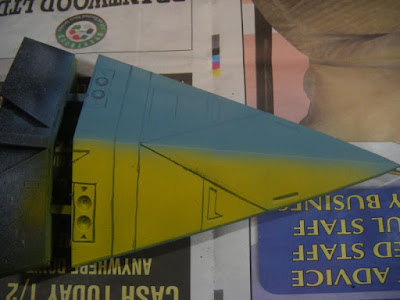

As for the painting afterwards, the priming went well as did the recess shading and drybrushing I did. I hit a problem when I went to airbrush the pale blue colour - the paint came out much faster than expected, so I ended up having to do several thin coats over the top to even it out and that obscured all the pre-shading/highlighting work I'd done. I decided to gloss varnish it and apply an oil wash for the panel lining (just the varnishing done so far).

3D Printing

I installed the new hotend and fan on Sunday and then had a bit of an issue - for some reason the auto-leveling probe wasn't working. I took back apart to check the wiring, put it back together - still not working. After asking for some advice, I re-flashed the firmware - still not working. I took it apart again, looked to see if anything was up with the wiring that I hadn't spotted the first time, didn't see (or touch) anything, put it back together and...it was working.

Reflashing the firmware meant that it was reset to factory defaults. I therefore needed to recalibrate it. Before doing that I ran a couple of test prints - it's just as well I did as I could tell from the surface quality that I'd knocked a few things off kilter while replacing the parts. After making adjustments and running test prints after each I got to a point where everything was good again.

The problem was I was still getting stringing. I ran more test pieces with different retraction settings, to no avail - I would need to increase the retraction distance and speed to a point where it would then cause under-extrusion when it started printing again. So I tried a different tack - printing at a lower temperature. Dropping from 210C to 190C seems to have done the trick. It was also a good excuse to print a couple of models I haven't printed before.

|

| 210C |

|

| 200C |

|

| 190C |

|

| Different dragon, 200C and 190C |

I'm still not sure what is causing the stringing at 210C - I'd been printing at that temperature for months without issue. It wasn't the hotend (although changing it was worth doing as it was well and truly gunked up). I could probably have got away with just changing the heatbreak, but wasn't sure which one I needed to buy.

With that done, I decided to return to testing speed and acceleration values for my starship printing. I also wanted to see how parts like the cabin partitions would come out at 0.16mm layer height (I'd previously printed them at 0.12mm). I got the first two prints done today:

|

| Left 250 mm/s/s; right 500 mm/s/s |

One was printed at 250 mm/s/s, the other at 500 mm/s/s. Both printed the details OK, but I think for the higher acceleration (500 mm/s/s) I might need to increase the flow rate slightly as there was some under-extrusion at the start of some layers. I'll need to do another print at 250mm/s/s acceleration, this time at 190C to confirm that it's the acceleration rather than the temperature causing that under-extrusion.

Once I've got these test prints done, I think I'll print out the last 1:270 scale Traveller ship. After that, I'm not sure what will be next.